1. Rongga penyegelan yang mengencangkan sendiri: Katup globe suhu tinggi bertekanan tinggi memiliki desain penyegelan yang diperkuat tekanan, dengan bevel las standar di ujung saluran masuk dan keluar.

2. Sistem penyegelan paduan keras: Permukaan penyegelan cakram/dudukan katup terbuat dari paduan tungsten-kromium-kobalt berbasis kobalt, dengan batas ketahanan suhu 650℃ dan peningkatan ketahanan aus sebesar 300%. Setelah 50.000 siklus pembukaan dan penutupan, tingkat integritas permukaan penyegelan adalah ≥98%.

3. Batang katup komposit berkekuatan tinggi: Matriks yang ditempa dan diberi perlakuan panas ditambah perlakuan nitridasi permukaan.

4. Kotak isian penghambat korosi rongga dalam: Inhibitor korosi ditambahkan untuk mencapai nol kebocoran, mengurangi torsi gesekan hingga 60% dari struktur standar.

Standar Desain: ASME B16.34M

Panjang Struktur: UKM B16.10

Pengujian dan Inspeksi: API 598

Tekanan - Suhu: ASME B16.34

Identifikasi Produk: ASME B16.34

| Tekanan nominal | 150LB | 300LB | 600LB | 900LB | 1500LB | 2500LB | |

| Tekanan kerja | 2.0 | 5.0 | 10.0 | 15.0 | 25.0 | 45.0 | |

| suhu yang tepat(℃) | ≤570 | ≤570 | ≤570 | ≤570 | ≤570 | ≤570 | |

| Media yang cocok | Uap dan nilai suhu tinggi dan tekanan tinggi lainnya | ||||||

| bahan | Bodi, kap mesin | Baja vanadium kromium molibdenum | |||||

| Cakram | Baja vanadium kromium molibdenum + paduan permukaan keras | ||||||

| Kursi | Baja vanadium kromium molibdenum + paduan permukaan keras | ||||||

| Batang katup | Baja vanadium kromium molibdenum | ||||||

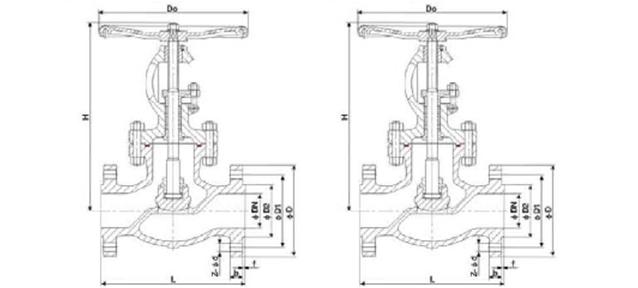

| hari | L | D | D1 | D2 | f | b | z-Φd | H | D0 |

| 150(LB) | |||||||||

| DN15 | 108 | 90 | 60.3 | 35 | 2 | 8 | 4-Φ16 | 235 | 125 |

| DN20 | 117 | 100 | 70 | 43 | 2 | 9 | 4-Φ16 | 241 | 125 |

| DN25 | 127 | 110 | 79.4 | 51 | 2 | 9.6 | 4-Φ16 | 242 | 125 |

| DN32 | 140 | 115 | 89 | 63.5 | 2 | 11.2 | 4-Φ16 | 280 | 160 |

| DN40 | 165 | 125 | 98.4 | 73 | 2 | 12.7 | 4-Φ16 | 315 | 160 |

| DN50 | 203 | 150 | 120.7 | 92 | 2 | 14.3 | 4-Φ19 | 350 | 200 |

| DN65 | 216 | 180 | 139.7 | 105 | 2 | 15.9 | 4-Φ19 | 370 | 200 |

| DN80 | 241 | 190 | 152.4 | 127 | 2 | 17.5 | 4-Φ19 | 385 | 250 |

| DN100 | 292 | 230 | 190.5 | 157.2 | 2 | 22.3 | 8-Φ19 | 454 | 250 |

| DN125 | 356 | 255 | 216 | 185.7 | 2 | 22.3 | 8-Φ22.5 | 472 | 355 |

| DN150 | 406 | 280 | 241.5 | 216 | 2 | 23.9 | 8-Φ22.5 | 541 | 355 |

| DN200 | 495 | 345 | 298.5 | 270 | 2 | 27 | 8-Φ22.5 | 590 | 450 |

| DN250 | 622 | 405 | 362 | 324 | 2 | 28.6 | 12-Φ25.5 | 780 | 450 |

| DN300 | 698 | 485 | 438 | 381 | 2 | 30.2 | 12-Φ25.5 | 870 | 500 |

| DN350 | 787 | 535 | 476.3 | 413 | 2 | 33.4 | 12-Φ28.5 | 900 | 600 |

| DN400 | 914 | 595 | 540 | 470 | 2 | 35 | 16-Φ28.5 | 1250 | 600 |

| DN450 | - | 635 | 578 | 533.4 | 2 | 38.1 | 16-Φ32 | - | 610 |

| 300(LB) | |||||||||

| DN15 | 152 | 95 | 66.7 | 35 | 2 | 12.7 | 4-Φ16 | 241 | 125 |

| DN20 | 178 | 115 | 82.6 | 43 | 2 | 14.3 | 4-Φ19 | 241 | 125 |

| DN25 | 203 | 125 | 89 | 50.8 | 2 | 15.9 | 4-Φ19 | 283 | 160 |

| DN32 | 216 | 135 | 98.5 | 63.5 | 2 | 17.5 | 4-Φ19 | 320 | 200 |

| DN40 | 229 | 155 | 114.3 | 73 | 2 | 19.1 | 4-Φ22.5 | 322 | 200 |

| DN50 | 267 | 165 | 127 | 92.1 | 2 | 20.7 | 8-Φ19 | 345 | 200 |

| DN65 | 292 | 190 | 149.2 | 104.8 | 2 | 23.9 | 8-Φ22.5 | 377 | 250 |

| DN80 | 318 | 210 | 168.3 | 127 | 2 | 27 | 8-Φ22.5 | 464 | 280 |

| DN100 | 356 | 255 | 200 | 157.2 | 2 | 30.2 | 8-Φ22.5 | 490 | 355 |

| DN125 | 400 | 280 | 235 | 185.7 | 2 | 33.4 | 8-Φ22.5 | 614 | 400 |

| DN150 | 444 | 320 | 270 | 216 | 2 | 35 | 12-Φ22.5 | 700 | 450 |

| DN200 | 559 | 380 | 330.2 | 270 | 2 | 39.7 | 12-Φ25.5 | 777 | 500 |

| DN250 | 622 | 445 | 387.4 | 323.8 | 2 | 46.1 | 16-Φ28.5 | 935 | 550 |

| DN300 | 711 | 520 | 450.8 | 381 | 2 | 49.3 | 16-Φ32 | 997 | 600 |

| DN350 | 762 | 585 | 514.4 | 412.8 | 2 | 52.4 | 20-Φ32 | 1058 | 650 |

| DN400 | 864 | 650 | 571.5 | 470 | 2 | 55.6 | 20-Φ35 | 1320 | 700 |

| 600(LB) | |||||||||

| DN15 | 165 | 95 | 66.7 | 35 | 7 | 14.3 | 4-Φ16 | 245 | 156 |

| DN20 | 190 | 115 | 82.6 | 43 | 7 | 15.9 | 4-Φ19 | 245 | 161 |

| DN25 | 216 | 125 | 89 | 50.8 | 7 | 17.5 | 4-Φ19 | 290 | 187 |

| DN32 | 229 | 135 | 98.4 | 63.5 | 7 | 20.7 | 4-Φ19 | 325 | 214 |

| DN40 | 241 | 155 | 114.3 | 73 | 7 | 22.3 | 4-Φ22.5 | 330 | 252 |

| DN50 | 292 | 165 | 127 | 92.1 | 7 | 25.4 | 8-Φ19 | 345 | 430 |

| DN65 | 330 | 190 | 149.2 | 104.8 | 7 | 28.6 | 8-Φ22.5 | 365 | 480 |

| DN80 | 356 | 210 | 168.3 | 127 | 7 | 31.8 | 8-Φ22.5 | 465 | 530 |

| DN100 | 432 | 275 | 216 | 157 | 7 | 38.1 | 8-Φ25.5 | 520 | 650 |

| DN125 | 508 | 330 | 266.7 | 185.7 | 7 | 44.5 | 8-Φ28.5 | 635 | 750 |

| DN150 | 559 | 355 | 292.1 | 216 | 7 | 47.7 | 12-Φ28.5 | 763 | 850 |

| DN200 | 660 | 420 | 349.2 | 270 | 7 | 55.6 | 12-Φ32 | 845 | 1050 |

| DN250 | 787 | 510 | 431.8 | 323.8 | 7 | 63.5 | 16-Φ35 | 930 | 1257 |

| DN300 | 838 | 560 | 489 | 381 | 7 | 66.7 | 20-Φ35 | 1010 | 1468 |

| DN350 | 889 | 605 | 527 | 412.8 | 7 | 69.9 | 20-Φ38 | 1090 | 1623 |

| DN400 | 991 | 685 | 603.2 | 470 | 7 | 76.2 | 20-Φ41 | 1140 | 1816 |

| 900(LB) | |||||||||

| DN50 | 368 | 215 | 165.1 | 92.1 | 7 | 38.1 | 8-Φ25.5 | 430 | 320 |

| DN65 | 419 | 245 | 190.5 | 104.8 | 7 | 41.3 | 8-Φ28.5 | 530 | 320 |

| DN80 | 381 | 265 | 190.5 | 127 | 7 | 38.1 | 8-Φ28.5 | 580 | 360 |

| DN100 | 457 | 290 | 235 | 157.2 | 7 | 44.5 | 8-Φ32 | 690 | 450 |

| DN125 | 559 | 350 | 279.4 | 185.7 | 7 | 50.8 | 8-Φ35 | 780 | 560 |

| DN150 | 610 | 380 | 317.5 | 216 | 7 | 55.6 | 12-Φ32 | 890 | 630 |

| DN200 | 737 | 470 | 393.7 | 270 | 7 | 63.5 | 12-Φ38 | 1240 | 720 |

| DN250 | 838 | 545 | 470 | 323.8 | 7 | 69.9 | 16-Φ38 | 1651 | 760 |

| 1500(LB) | |||||||||

| DN65 | 419 | 245 | 190.5 | 104.8 | 7 | 41.6 | 8-Φ28.5 | 530 | 400 |

| DN80 | 470 | 265 | 203.2 | 127 | 7 | 47.7 | 8-Φ32 | 590 | 450 |

| DN100 | 546 | 310 | 241.3 | 157.2 | 7 | 54 | 8-Φ35 | 710 | 500 |

| DN125 | 673 | 375 | 292.1 | 185.7 | 7 | 73.1 | 8-Φ41 | 780 | 560 |

| DN150 | 705 | 395 | 317.5 | 215.9 | 7 | 82.6 | 12-Φ38 | 904 | 630 |

| DN200 | 832 | 485 | 393.7 | 270 | 7 | 92.1 | 12-Φ45 | 1140 | 560 |

| 2500(LB) | |||||||||

| DN65 | 508 | 265 | 196.8 | 104.8 | 7 | 57.2 | 8-Φ32 | 740 | 400 |

| DN80 | 578 | 305 | 228.6 | 127 | 7 | 66.7 | 8-Φ35 | 780 | 450 |

| DN100 | 637 | 355 | 273 | 157.2 | 7 | 76.2 | 8-Φ41 | 860 | 560 |

| DN125 | 794 | 420 | 323.8 | 185.7 | 7 | 92.1 | 8-Φ48 | 930 | 630 |

| DN150 | 914 | 485 | 368.3 | 216 | 7 | 108 | 8-Φ54 | 1070 | 560 |

| DN200 | 1022 | 550 | 438.2 | 270 | 7 | 127 | 12-Φ54 | 1180 | 630 |

Alamat

No.1, Jalan 1 Utara, Kota Baru Stainless Steel, Jalan Barat Dunia Baja Lecong, Distrik Shunde, Kota Foshan, Provinsi Guangdong, Cina

Telp

Surel

Untuk pertanyaan tentang katup gerbang, katup globe, dan katup periksa atau daftar harga, silakan tinggalkan email Anda kepada kami dan kami akan menghubungi Anda dalam waktu 24 jam.